When you send business mail, the envelope is the first point of contact with your customer, and it sets the standard for its contents. Your envelope layout also affects how accurately and quickly we can process your mail with our automatic machines.

This guide is designed to help you, by providing critical parameters and layout diagrams for the most commonly used DL and C5 sized paper based envelopes.

Please use these size constraints as a guide for your mail sizes. Check with your printer or stationer if you are concerned that your items will not meet these requirements.

Length

This must be a minimum of 154mm and a maximum of 240mm.

Height

This must be a minimum of 110mm and a maximum of 165mm.

Recommended minimum size: 110 x 154mm. Recommended maximum size: 165mm x 240mm.

Shape

Mail items should be rectangular in shape and the longest edge must be a minimum of 1.4 times the length of the shorter edge.

We recommend standards C5, C6 or DL envelopes, all of which meet our size guidelines. Items should not be a portrait or square format.

Paper Weight

Envelope paper should be a minimum of 70gsm, and single piece mail a minimum of 100gsm before folding (the lower the paper weight, the thinner and less robust the mail item will be). There is an exception for postcards, where there is no minimum paper weight, but all mail pieces should be a minimum of 0.25mm thick.

Reflection

The background reflectivity of the address material should be at least 35% in the red region (600nm) when measured by a spectral reflectometer.

Water Absorbency

Water absorbency should be 15-35 gsm water in 1 minute. We require this because the absorbency of the mailpiece affects the migration of the ink used for codemarks and cancellation marks into the mail item. If the absorbency is too low then the ink will sit on the mailpiece surface resulting in smudging, whilst high absorbency causes the ink to be absorbed into the paper and marking it. In both cases our sorting equipment cannot read the codemark.

Thickness

Mail should be between 0.25mm and 5mm thick. Thickness variation should be no more than 2mm across height or length of mail item.

Weight

For maximum quality of service and to ensure that an item will pass through our automated equipment, items should weigh no more than 100g.

Flexibility

Items must be flexible enough to bend easily into an S-shape along the longest edge. Please do not enclose items such as coins, keys and thick card coupons. The minimum flexibility is pre-defined by the minimum paper weight. The maximum flexibility is defined as the force to deflect the mail item (with all enclosures) 5mm when placed between two fulcrums 75mm apart. Maximum 2kg force.

Opacity

The envelope paper needs to be at least 85% opaque. This will prevent any character of pattern on the inside from showing through the envelope material, preventing our equipment form reading the address.

Porosity

The paper used for postcards and single piece mail must have a porosity value between 400 and 700 ml/minute. The paper used for envelopes must have a porosity value greater than 400ml/minute.

Sealing

Ensure the item is securely continuously sealed on all sides, taking care to avoid a residue of gum on the item itself. Please do not use metal clips or staples.

Paper Colour

When sending items in envelopes the best colours to use are white, cream or light buff.

Please do not use dark coloured or red envelopes.

Fluorescence and Phosphorescence

The ink used for printing codemarks contains both phosphorescent and fluorescent materials. When passed beneath a high intensity long wave ultra violet light source this ink gives

out a strong light signal, which is read by the equipment. If the mail item contains impurities, our equipment could have difficulty in distinguishing the codemark from the background. The use of brightening agents, particularly within white envelopes, is common and generally does not cause problems as long as they are kept to a minimum.

Window size

There is no maximum or minimum size for a window. However, the window size is constrained by the length of the address, font size, number of lines of the address, address boundaries and the clear zones.

Gloss of the window film

Gloss is expressed as a unit, and refers to the amount of light that is reflected back from the surface being measured. The higher the unit, the glossier the surface being measured.

The recommended maximum value of gloss when measured at 60 degrees in accordance with ASTM 2457 is 150.

Haze of the window film

Haze is an indication of the clarity of the material being measured. The higher the haze the more difficult it is to see through the material. The recommended maximum value of haze when measured in accordance with ASTM D 1003 (Procedure A – Hazemeter) is 75%.

Position of the address within the window

In order to read and interpret the address, the automation equipment locates the position of the window and takes an image of the address. The complete address must be clearly visible through the window with a 2mm clear zone around it.

Strength of the window film

If window material can be safely handled during its production process, it will be strong enough to affix to an envelope. However, any wrinkling or creasing of the window will significantly affect the ability of our equipment to read the address. It is therefore essential that the window is robust enough not to become deformed.

Position of the address within the window

In order to read and interpret the address, the automation equipment locates the position of the window and takes an image of the address. The complete address must be clearly visible through the window with a 2mm clear zone around it.

Strength of the window film

If window material can be safely handled during its production process, it will be strong enough to affix to an envelope. However, any wrinkling or creasing of the window will significantly affect the ability of our equipment to read the address. It is therefore essential that the window is robust enough not to become deformed.

Address background

Our equipment must be able to clearly differentiate the address information from the envelope background. Two things are important: the contrast ratio between the address and the background and the fact that the address must be darker than the background (no reverse contrast is allowed). This applies whether addresses are printed directly onto the envelope, or on an insert behind a window.

Wherever the address is printed in this area, and for 5mm all around the address, the background must have:

● A spectral reflectance of at least 30% higher than the colour used for the address

(i.e. the minimum reflectance between the address and the background must be 30%) when measured in the red region (600nm) with a spectral reflectometer

● A minimum spectral reflectance of 35% (in the red 600nm region)

● Positive contrast (address darker than the background).

Text spacing

All fonts used should be true type. Proportionately spaced text is not easily read by OCR, although increasing the gap between characters by 0.75mm dramatically improves the rate at which addresses can be read.

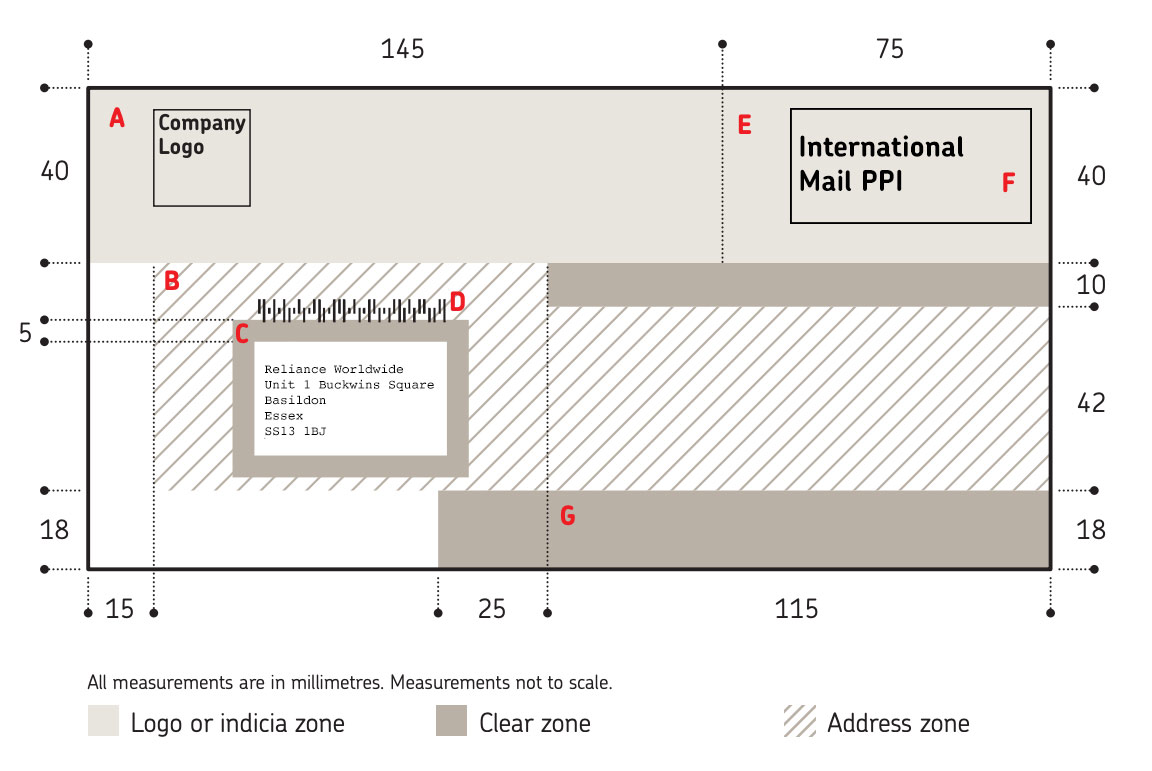

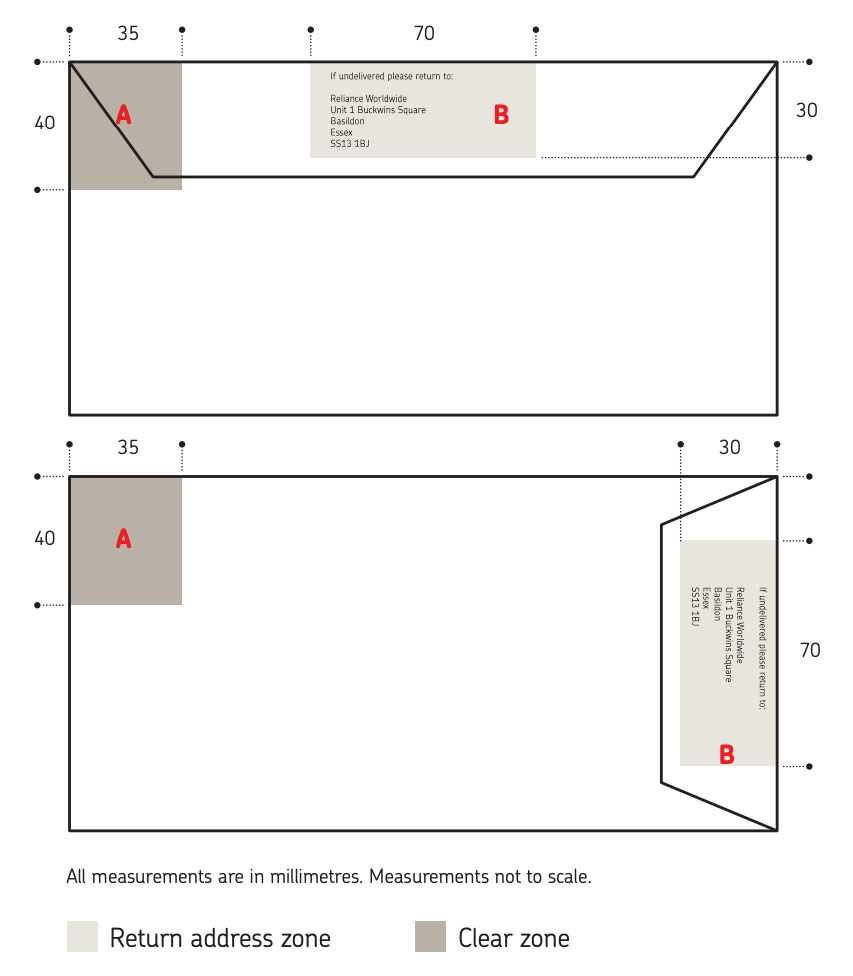

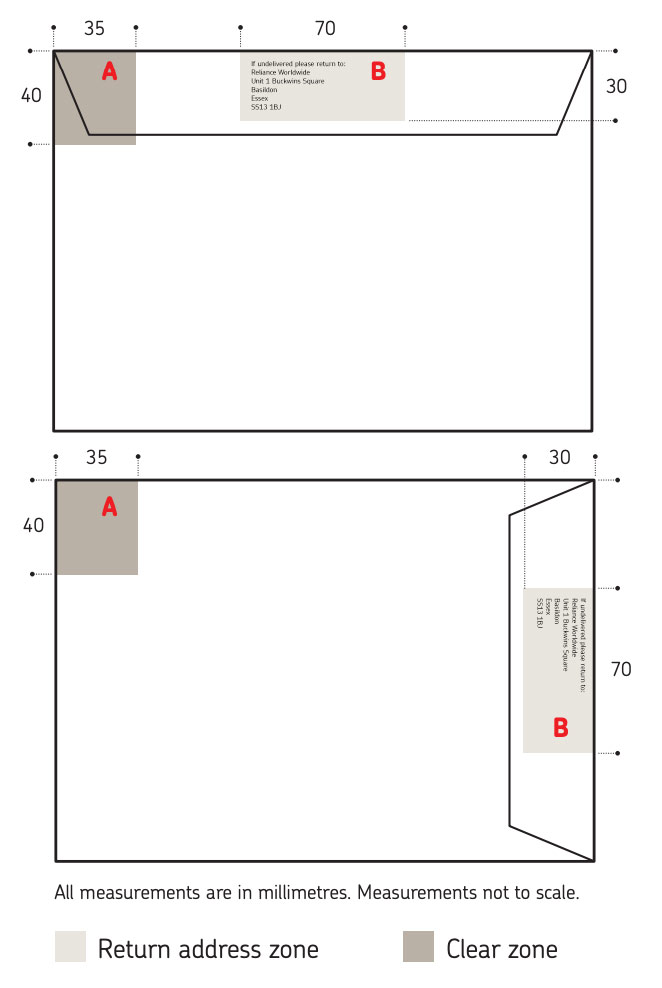

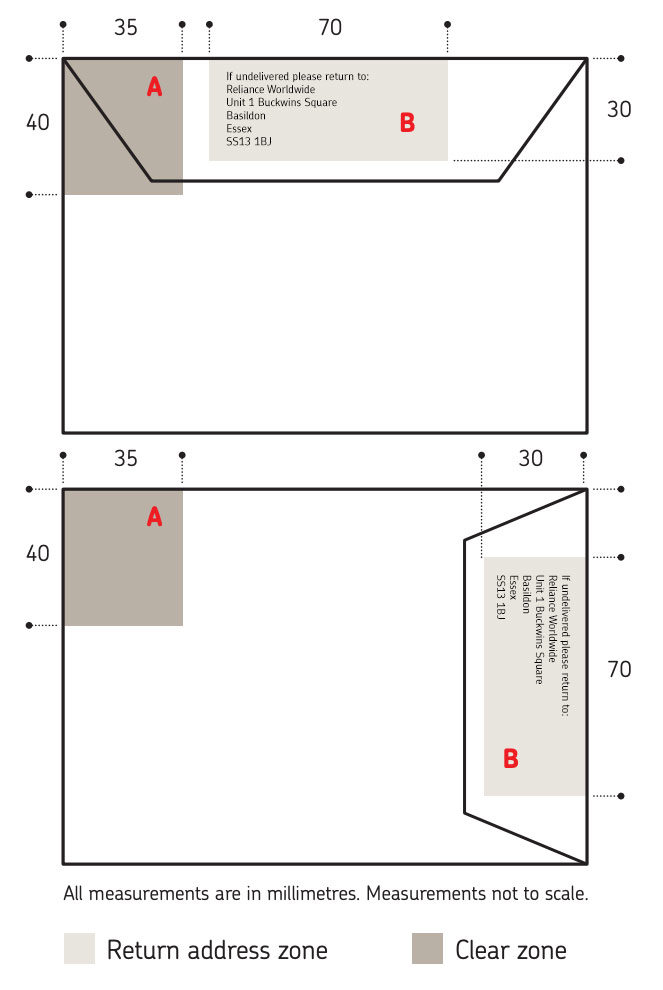

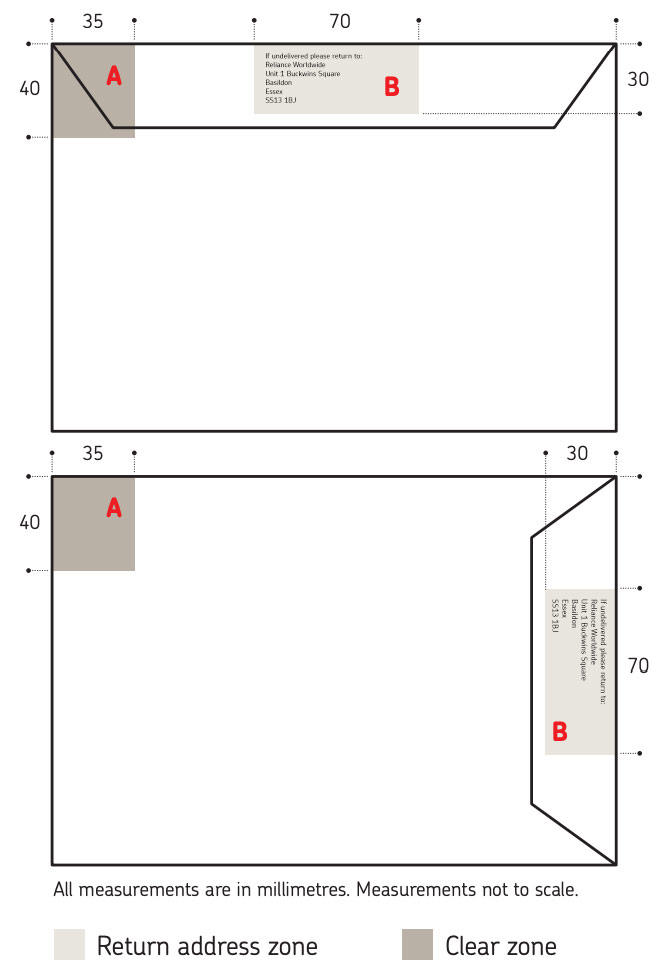

Return address location

This should be placed on the rear of the envelope, avoiding the rear quality mark zone in the top left hand corner. Please refer to the diagrams in Section 1.

| Printing Characteristics | |

|---|---|

|

Each line of the address must be made up of characters of the same font and size |

|

|

Characters printed per inch (25.4mm) |

10 —12 characters |

|

Spacing between words |

10mm (maximum) |

|

Uniform spacing between lines |

1mm (minimum) |

|

Maximum characters per line of address |

32 characters (including spaces) |

|

Number of lines per inch (25.4mm) |

6 lines |

|

Skew of address block |

3 degrees |

|

Negative contrast is not allowed |

|

|

Print quality must be such that characters are not blurred, smudged or incomplete |

|

|

Separation between the two parts of the postcode |

2 white spaces |

|

Preferred print colour for the address |

Black |

|

Yellow print must not be used |

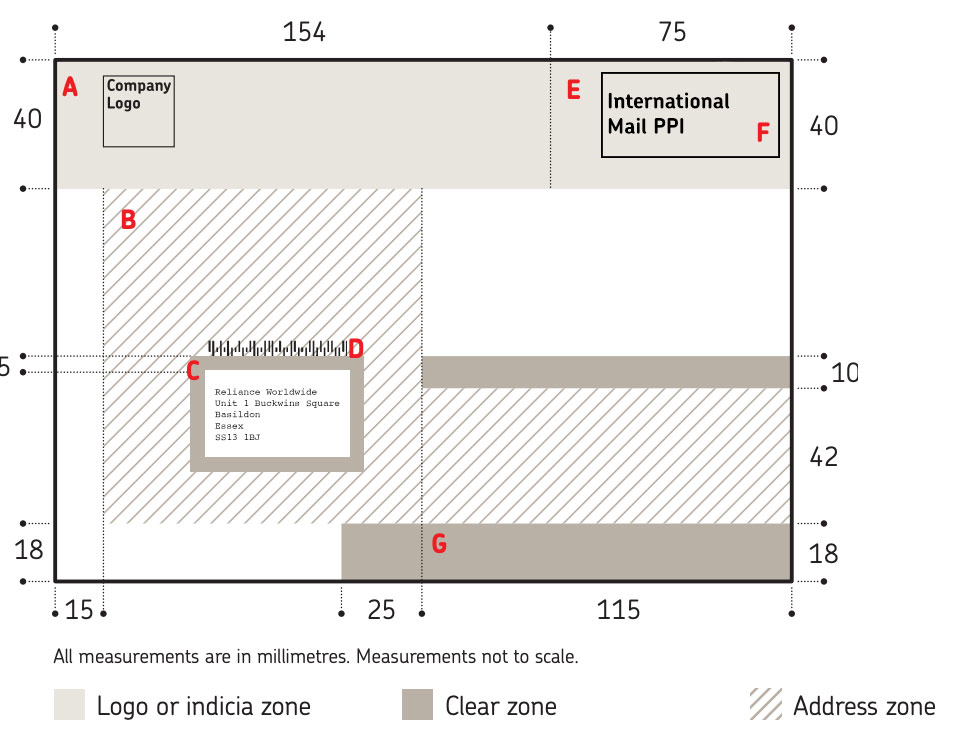

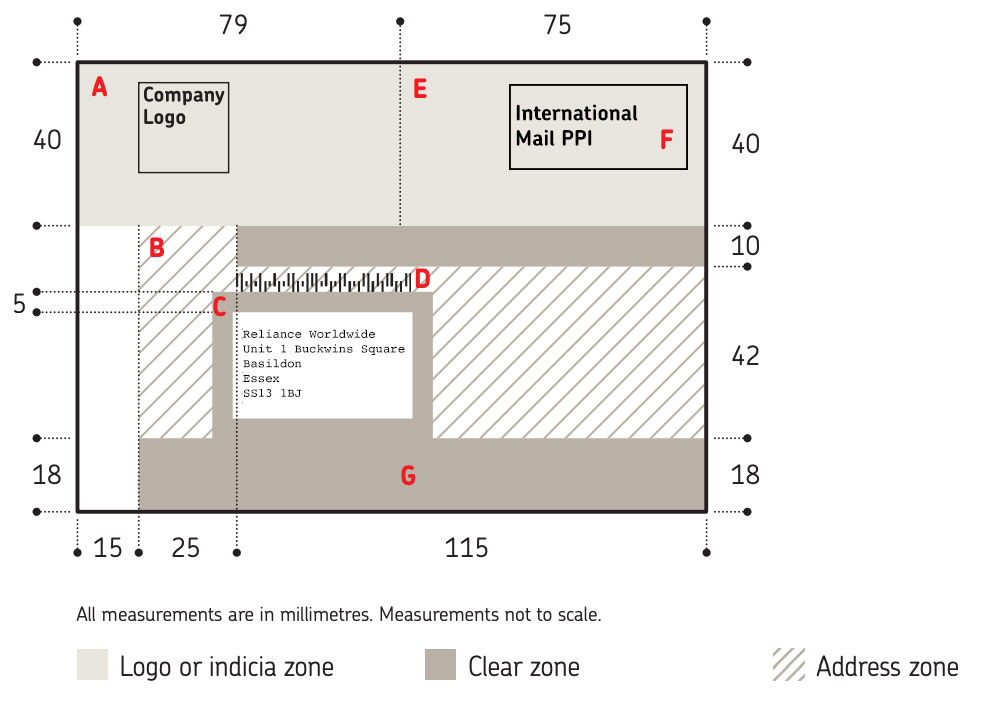

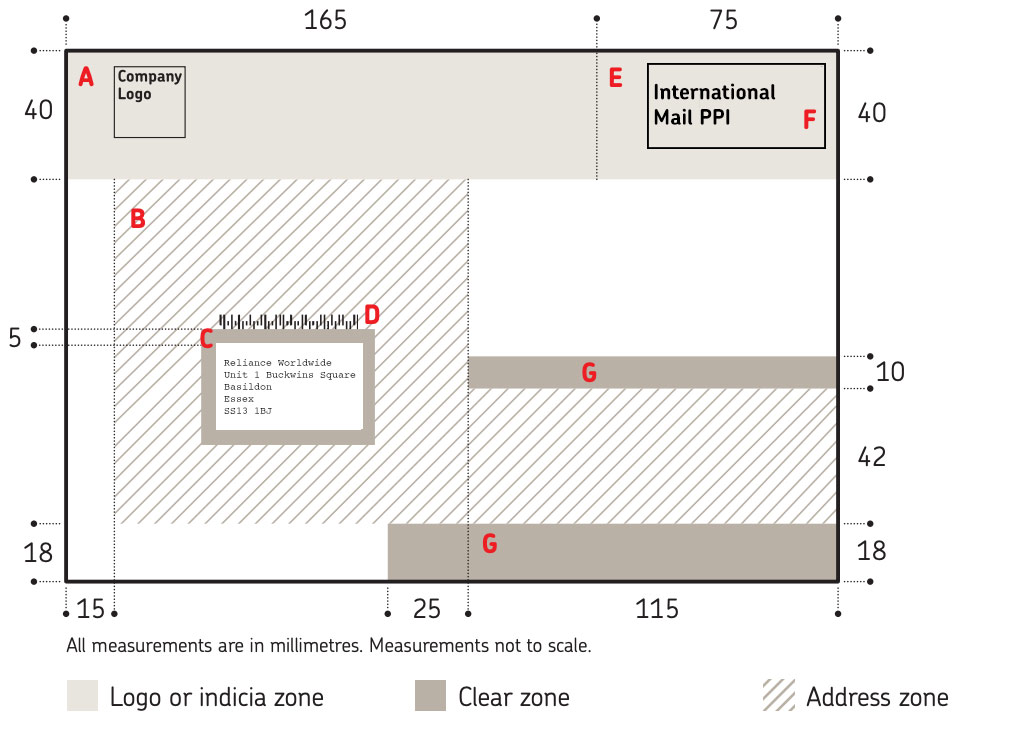

In order for the mail piece to be automatically and accurately processed, it is important that key elements can be easily located and identified.This can be achieved by keeping certain areas of the mailpiece are kept clear of anything other than the required information. These key areas are:

● Address block

● Codemark clear zone

● Indicia zone

● Rear quality mark zone

Codemarks are printed in codemark clear zones. The envelope colour in these areas must have a minimum accepted spectral reflectance of 28% in the red region (600nm). Please see the envelope diagrams in Section 1 for location of the clear zones.